PE automatic cutting machine is mainly based on the requirements of PE foam sheet/board for fixed length, fixed width cutting, can work online or offline, cutting size is accurate. Products are suitable for electronic products, toys, fruits, valuable or fragile items packaging, also used for mattresses, children's crawling MATS, splicing MATS, etc.

This machine is a deeply processing equipment of EPE foam sheet/film products, mainly used for the tectorial surface of EPE foam sheet/film.The material can be PE film, plated Aluminium foll, plastic-coated paper, plastic-coated fabric and so on. Laminated foam sheet increases intensity,waterproof ,and can be printed character, picture,improving the products grade, widely used for the packing of box lining, life vest, wooden floor underlayer. Car havelock,Motor adumbral cushion,household appliance.high-top Pottery and so on.

EPE foam net machine is a kind of new soft packing material. Mainly used in the production of PE foam net, it is through extruder and mold production of different sizes of products. Products are mainly used in various fruits, red wine , flowers and various fragile products packaging.

EPE foam pipe is a kind of new-type foam material and it is widely used in the jacket of air conditioner, pipeline heat insulation, toy guardrail and recreation places etc. due to its high foam ratio, good elasticity and heat preservation.

EPE foam sheet machine is a single stage extruding and foaming equipment with large L/D. It takes polyethylene resin with low density as raw material. This production line is the most ideal physical PE forming unit in the world. It has continuons stable performance with high yield,wide range of foaming ratio,high automation and reliability, products have a wide range of applications.

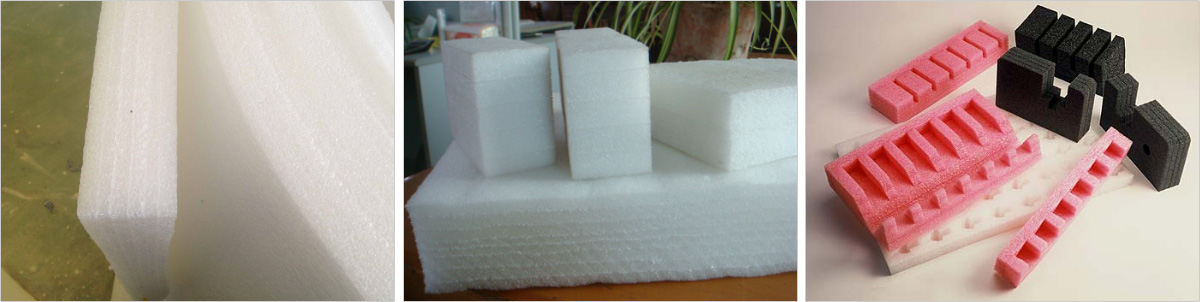

The foam sheet has the features of dampproof , shockproof, soundproof, heat preservation and good plasticity.

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program.

This production line adopts double-screw foam sheet extrusion technology . PSP foam sheet is a kind of new-type packing material with the features of heat preservation, safety,sanitation and good plasticity. It’s mainly used to make various types of food containers, such as lunch box, dinner trays, bowls etc by thermoforming. It’s also can be used to make advertisement board, industrial products packing and so on. It has stable performance, big capacity, high automation and yields quality products.

XPS foam board,n amed as polystyrene extrusion board(XPS for short) has a flawless closed-pore cell structrue. Its density,water absorption, coefficient of heat conducting and the coefficient of steam pervasion are all lower that those of other board heat preservasion materials and they have the charact eristics of strong intensity, light material, airtight, anticorrosion, aging resistance, low cost, etc. It has been widely used in the fields of heat insulation in the construction indusry,frost resistance of the highway,railway,airport,square and household fitment.It is generally acknowledged the best heat preservation material in the market at present.

Pe foam recycling machine is to put PE foam products into the extruder to melt, at the same time to release the gas in the product and filter the impurities in the product, and then through the die head extrusion drawing, cooling, cutting, drying, packaging, to ensure the quality of particles.

Ps foam recycling machine is to put Ps foam products into the extruder to melt, at the same time to release the gas in the product and filter the impurities in the product, and then through the die head extrusion drawing, cooling, cutting, drying, packaging, to ensure the quality of particles.

This machine is mainly used in thickening EPE Foam Sheet with air as medium of heat conducting, making use of high temperature air to melt EPE Foam Sheet each other, then pressed by the steel roller. This thickened sheet is used widely in construction material, packaging, shoes making, bags and suitcases industry etc. reason structure, high production efficiency, easy to operate etc.

The working mode of the machine is divided into vertical and horizontal, mainly according to the product fit thickness to distinguish. Vertical equipment is suitable for low thickness products, horizontal equipment is suitable for large thickness products.