XPS HEAT INSULATION FOAM BOARD EXTRUSION LINE

Product Description

XPS foam board machine is a two-stage extruder, different diameter screw combinations can meet the production needs of different products.

Equipment because of its use of blowing agents and different requirements for the product, its configuration and price are also very different.

Products are mainly used in construction, thermal insulation, waterproof, moisture-proof, sound insulation and other functions.

Parameter List

Model | Unit | HXXPS135/150 | HXXPS-150/170 | HXXPS-170/200 |

| Screw Diameter | mm | 135/150 | 150/170 | 170/200 |

Thickness Of Board | mm | 20-80 | 20-100 | 40-120 |

| Width Of Board | mm | 600,900 | 600,900,1200 | 600,900,1200 |

| Length Of Board | mm | 1200,1250,2450,2500

|

| Capacity | kg/h | 280-320 | 300-360 | 380-500 |

| Total Power | kw | 300 | 380 | 400 |

| Overall Size(L×W×H) | m | 35×10×4 | 38×10×4 | 40×10×4 |

| Total Weight | T | 28 | 30 | 33 |

| The device model can be customized according to the requirements. |

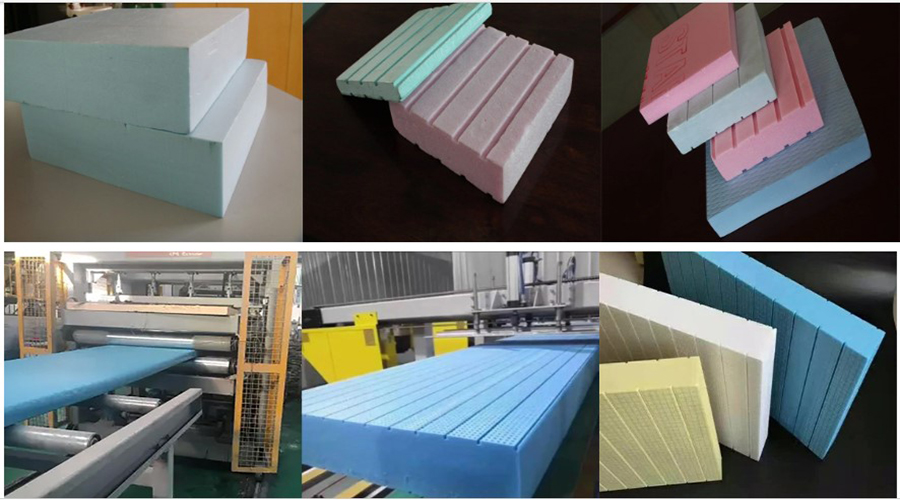

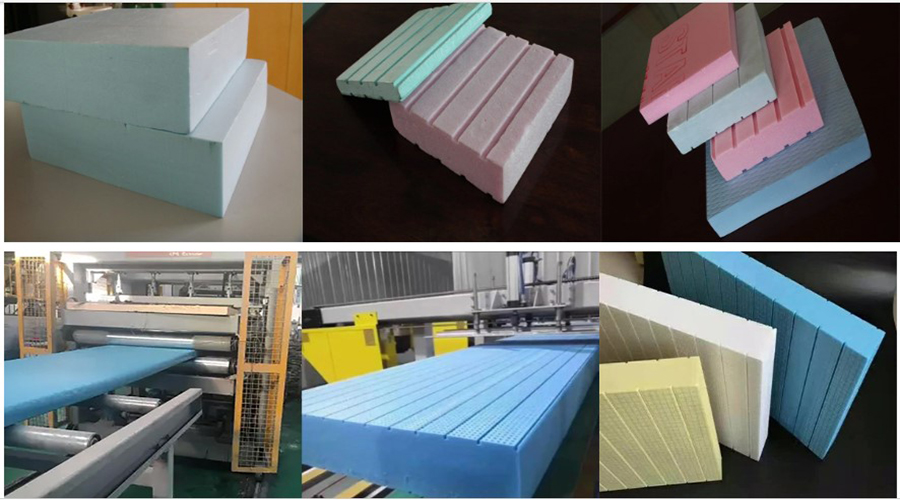

Product Picture

XPS foam board, named as polystyrene extrusion board (XPS for short)has a flawless closed-pore cell structure. lts density,water absorption, coeffcient of heat conducting and the coeficient of steam pervasion are all lower than those of other board heat preservasionmaterials and they have the charact eristics of strong intensity, ight material, airtight anticorosion, aging resistance, low cost, etc. t has been widelyused in the fields of heat preservation and heat insulation in the construction industry, frost resistance of the highway, railway, airport, squareand household fitment. lt is generally acknowledged the best heat preservation material in the market at present.

COOPERATION BRAND

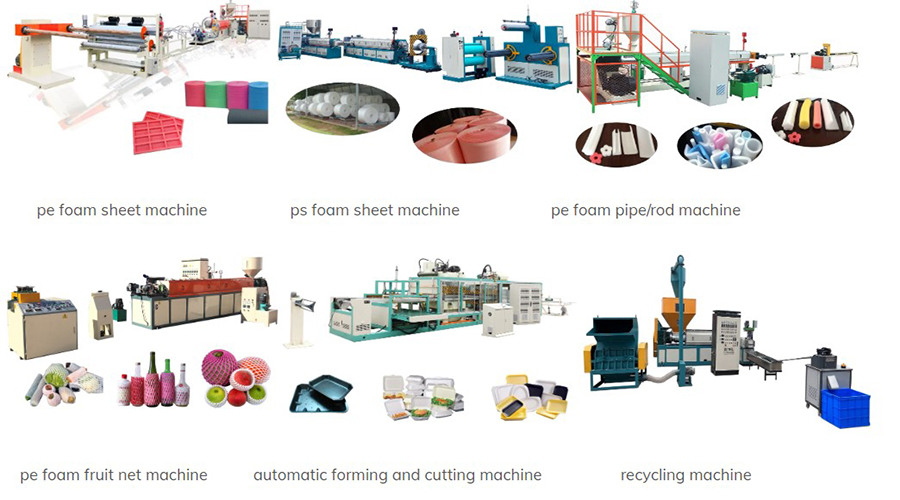

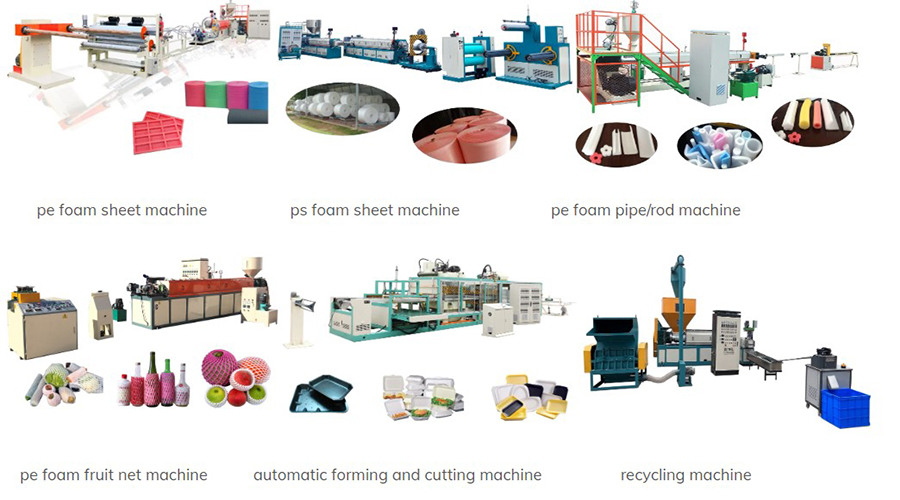

Our Other Products

FAQ

Q1.What materials are needed for equipment production?

A1:pe machine: polyethylene, talc powder, GMS, liquid butane.

ps machine: polystyrene, talc powder, liquid butane.

If you want to produce color products, you also need to use color master.

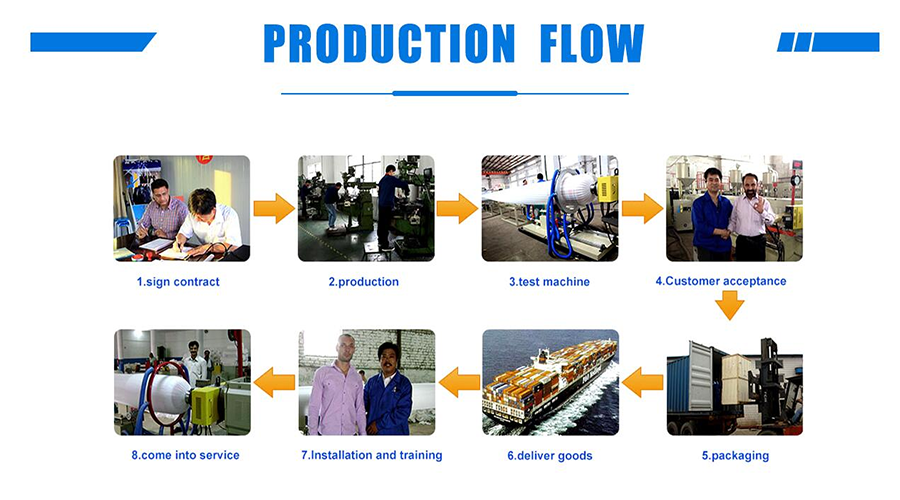

Q2.How long is the production cycle of the equipment?

A2:The production cycle is determined according to the equipment model, quantity and workshop production tasks.

The minimum equipment cycle is about 20-30 days.

Q3.Minimum order quantity?

A3:Our minimum order quantity for equipment is 1 set.

Q4.When can I get a quote?

A4:We usually quote within 24 hours of receiving your inquiry. If you need a price very urgently, please call us on email so we will give priority to your inquiry.

Q5.Can I put my logo on the packaging?

A5:Yes, we can do OEM service, but you need to send us your packaging and logo design.

Q6.What kind of payment do you accept?

A6:T/T, L/C at sight, cash