Epe Insulation Foam Pipe Tube Extruder Maker Machine

Flow chart of PE pipe extrusion line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder→ color band extruder → mould and calibrator → vacuum calibration machine → cooling tank→ haul-off machine → cutting machine → stacker(Winding machine)

Parameter List

| Model | Unit | HXEPEG-70 | HXEPEG-75 | HXEPEG-90 | HXEPEG-105 | HXEPEG-120 | HXEPEG-135 |

| Screw diameter L/D |

| 70/55:1 | 75/55:1 | 90/55:1 | 105/55:1 | 120/55:1 | 135/55:1 |

| Pipe specification | mm | 20-40 | 20-50 | 20-80 | 20-100 | 20-120 | 20-130 |

| Rod specification | mm | 6-30 | 8-35 | 15-50 | 18-70 | 20-80 | 30-100 |

| Cooling method | Water cooling and Air cooling |

| Overall size | m | 15*1.3*1.7 | 16*1.3*1.7 | 18*1.5*2 | 20*1.8*2 | 22*2*2 | 25*2*2 |

| The device model can be customized according to the requirements. |

Product Picture

Main Usages :

a. Indoor water pipe,hot water pipe and purified water delivery pipe

b. Liquid food delivery pipe

c. Used in the solar water heater system,central air conditioning duct system and ground radiation heating system

d. Used in electroplating/petroleum and chemical plant delivery pipe system,and so on.

Equipment Characteristics

* V.F driving for speed regulation. screw with independent heating zones to insure easy operation, easy trouble shooting, precise heating and curing.

* Temperature control system. Stable and reliable.

* Circulation water cooling. (Water tower or chiller)

* The head employed automatic screen exchange system (with a hydraulic station) to save time and reduce wastage. About 30% may be saved.

Our Service

1. when we make the order, I will follow your order, update machine information and send to you

2. when finish the machine, we will pack the machine well and arrange ship send to you. when the machine got your factory we will send our rich experience engineers to your country install machine and train your worker till you satisfied with them

3. when you run the machine, if you have any problem our after-sales service person will solve your problem at first time.

4. our machine have 1 year guarantee and lifetime maintenance.

5. if you need any parts, we will supply them as a cost price.

Within 12 months after completing the install and testing.

All life time support maintenance but need pay charge for needed parts, phone support and technical support is free, if an engineer need to be dispatched, the buyer should be pay for the engineer travel and accommodation fee.

Equipment Use Brand

FAQ

Q: What should we prepare for EPE foam sheet extrusion machine?

A: You should prepare raw material (LDPE, talc powder, GMS, butane or gas), workshop, water line, electric line, compress air (if you need I can help you buy air compressor). We would supply workshop layout drawing for you.

Q: What's the trade term and payement term?

A: 30% or 50% T/T before production; Paid in full before shipment.

Q: Will you send the equipment to us directly after completion

A: Of course. But before delivery, we will test the equipment and send relevant videos to you. On the premise that the equipment can operate normally, we can send the equipment to you.

Q: Are you a supplier or a manufacturer?

A: We are a very experienced manufacturer. We are longkou hexing machinery company located in Yantai city, Shandong province with more than 20 years of production experience. Moreover, our company also has the right to import and export, so we can docking with you directly.

Q: Can your equipment meet our specified requirement?

A: Absolutely. We will change the relevant parameters of the equipment according to your requirements, for example: output, brand, voltage, color and so on, so as to better meet the production requirements of your factory.

Q: How to guarantee quality to customers?

A: We have very strict product quality control links. The leader of the company is a technical design background, so quality is the most important factor in our company. So the products we sell have stood the test of time and our customer buy-back rate is very high.

Q: What payment terms can we use to complete the transaction on time?

A: FOB, CIF, CFR, CIP, EXW etc. 30% before production, 70% before shipment. We prefer 100% T/T but also accept LC, The delivery time of our equipment is determined according to the order quantity. Once we receive your deposit, we will arrange production and delivery as soon as possible.

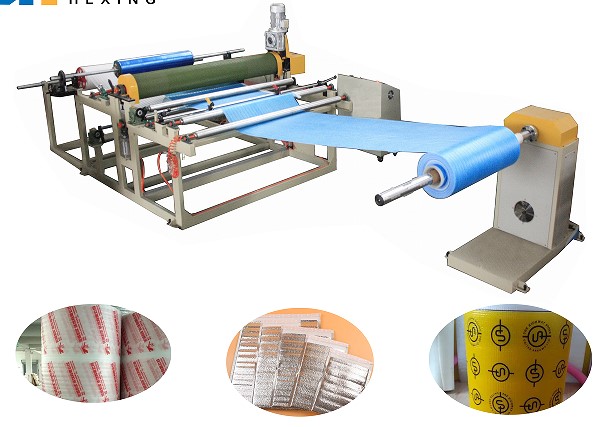

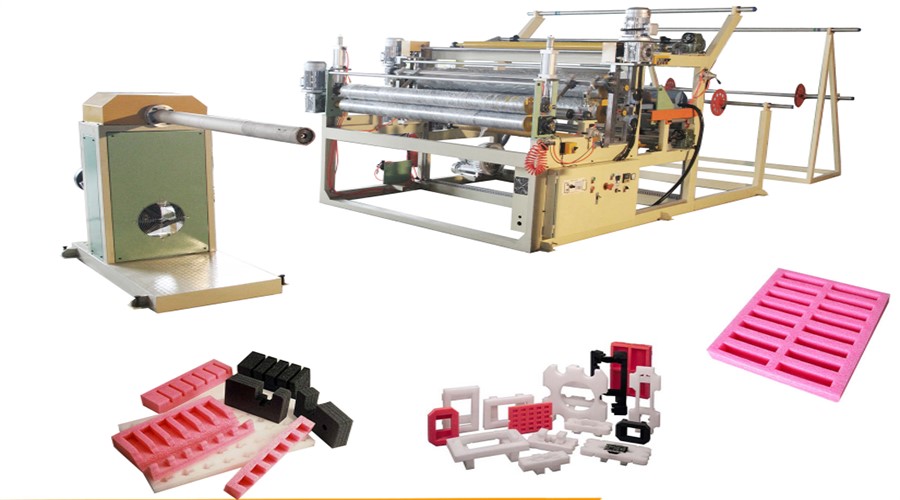

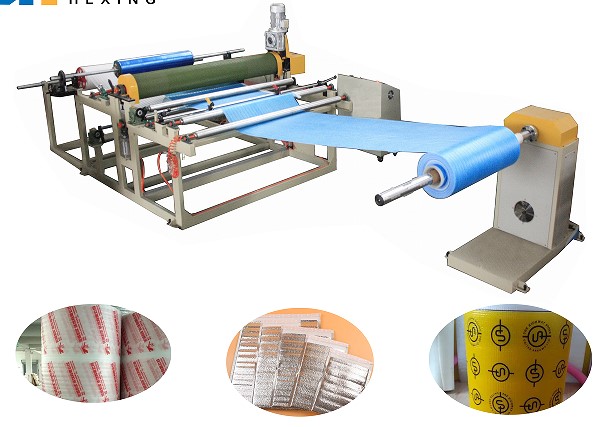

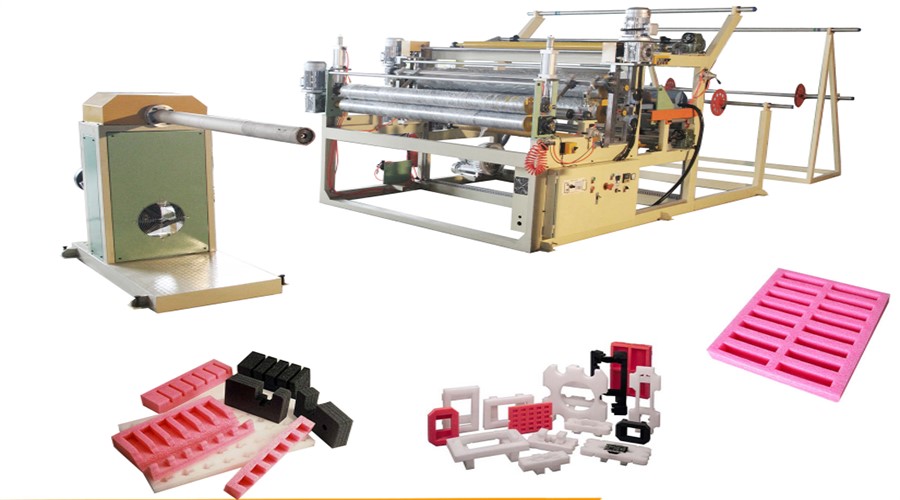

Related Products

pe foam sheet machine pe foam fruit net machine heating laminating machine

bonding machine pe foam platic recycling machie automatic forming and cutting machine