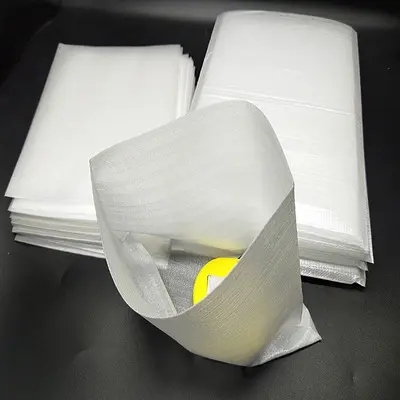

Q: what should we prepare for the foam food container production line?

A: You should prepare raw materials (LDPE), workshop, water line, electric line We can supply workshop layout drawing according to your workshop.

Q: What's the trade term and payement term?

A: 30% or 50% T/T before production; Paid in full before shipment.

Q: Will you send the equipment to us directly after completion

A: After the completion of the equipment, you must first come to the acceptance, confirm that there is no problem before delivery

Q: Are you a supplier or a manufacturer?

A: We are a very experienced manufacturer. We are longkou hexing machinery company located in Yantai city, Shandong province with more than 20 years of production experience. Moreover, our company also has the right to import and export, so we can docking with you directly.

Q: Can your equipment meet our specified requirement?

A: Absolutely. We will change the relevant parameters of the equipment according to your requirements, for example: output, brand, voltage, color and so on, so as to better meet the production requirements of your factory.

Q: How to guarantee quality to customers?

A: We have very strict product quality control links. The leader of the company is a technical design background, so quality is the most important factor in our company. So the products we sell have stood the test of time and our customer buy-back rate is very high.

Q: What payment terms can we use to complete the transaction on time?

A: FOB, CIF, CFR, CIP, EXW etc. 30% before production, 70% before shipment. We prefer 100% T/T but also accept LC, The delivery time of our equipment is determined according to the order quantity. Once we receive your deposit, we will arrange production and delivery as soon as possible.

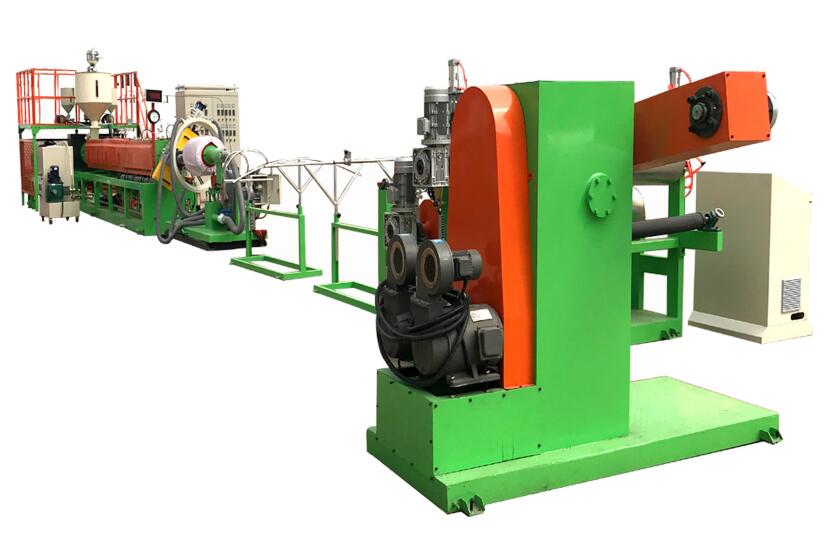

Q: What should we prepare for EPE foam sheet extrusion machine?

A: You should prepare raw material (LDPE, talc powder, GMS, butane or gas), workshop, water line, electric line, compress air (if you need I can help you buy air compressor). We would supply workshop layout drawing for you.